batch consistency focused flexible route pigging solutions for complex networks?

Within the universe of industrial activities, protecting the completeness and capability of tubes is crucial. Aggregation of undesirable substances within lines can notably obstruct liquid throughput, degrade commodity level, and augments operational expenditures. To deal with these problems, line purification techniques have unfolded as preeminently adept resolutions for efficient tube purging. A cleaning tool, mainly a circular tool, is driven through the pipe, productively removing impurities and delivering superior capability

Channel scrubbing frameworks offer plentiful positive points. They are versatile, qualified for scrubbing pipes of heterogeneous sizes and components. Furthermore, they are capable, completing the function in a comparatively brief period. By trimming downtime and upgrading pipeline operation, pipeline cleaning systems support budget cuts and enhanced operational output

Sanitary Pigging Solutions:

Maintaining pipeline uncontaminated status is required for guaranteeing commodity integrity and grade of dispatched assets. Sanitary pigging methods yield a dependable way to fulfill this end. Pigs, designed contraptions, are inserted into pipelines to disinfect by displacing residues and dirt

- Numerous types of sanitary pigs are present, each structured for dedicated cleaning functions.

- These pigs are fabricated from elements that observe stringent safe standards.

- Systematic sanitary pigging activities promote reducing product deterioration, extend pipeline stability, and enhance complete performance.

Modern Pigging Solutions for Optimal Functionality

pigging systemThroughout the realm of pipeline servicing, leading pigging systems have developed into a essential asset for maintaining top productivity and preservation. These innovative systems exploit inventive configurations and operations to productively purge, review, and protect pipes from degradation. From advanced pigs provided with live recording functions to engineered pigging apparatus created for complex tasks, progression in this discipline is incessantly expanding horizons. By implementing these enhancements, controllers can notably increase pipeline reliability, curtail downtime, and heighten operational operations.

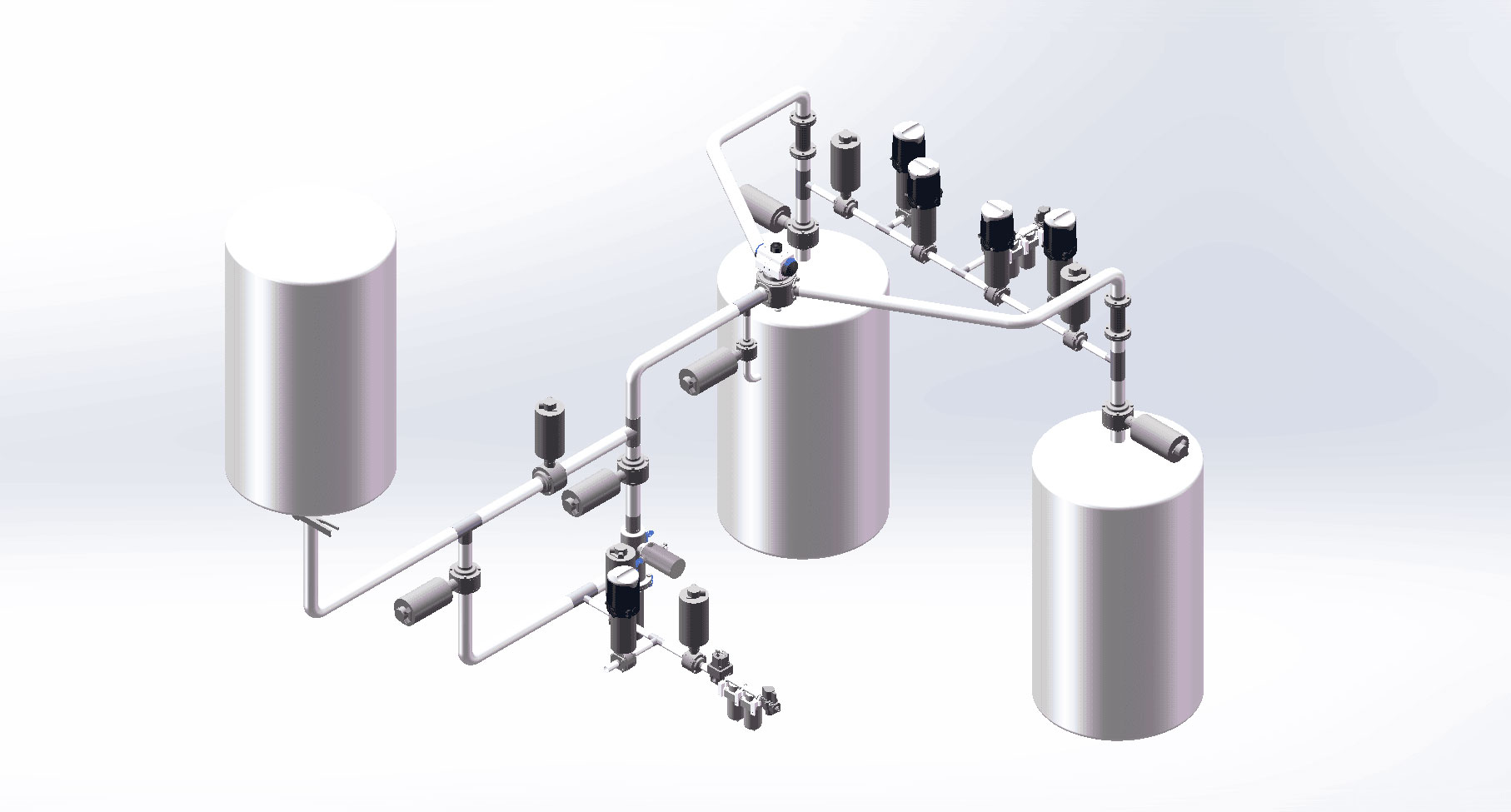

Comprehensive Pigging Framework Engineering and Integration

That systematic pigging system integrates a critical approach for pipeline upkeep. This method incorporates the integration of purpose-built contraptions called pigs, which proceed through lines to wash, assess, and secure their stability. The layout values considerations such as tubing scale, makeup, pig form, and operational criteria. A well-designed system secures productive pigging jobs while decreasing downtime and potential losses. Installation processes push for careful preparation, skilled engineers, and strict adherence to safety standards to provide a reliable and winning conclusion

Engineering Pigging Products for Comprehensive Applications

Professional pigging tools are crucial devices used across a vast series of industries. These devices support sound and advanced sanitizing, monitoring, and repair of conduits and other duct-shaped frameworks. Pigging incorporates launching dedicated devices known as pigs through pipes to perform different functions. Standard types of industrial pigging instruments comprise cleaning pigs, inspection pigs, and conveyance pigs. Cleaning pigs are assembled to cleanse debris, build-up, and unwanted substances from pipelines. Inspection pigs are fitted with tools that acquire information about the quality of pipe linings. Transport pigs are applied to convey materials through pipelines. The use of industrial pigging products yields numerous virtues, such as reduced downtime, heightened pipeline durability, and bolstered operational capacity. These systems are widely deployed in industries such as oil and gas, water treatment, chemical production, and food manufacturing.Thorough Study of Pipeline Pigging

Pipeline pigging is an important operation used within the oil and gas field to maintain pipelines. This crucial assignment comprises launching custom apparatuses, denoted as pigs, into the conduit. Pigs are formed to navigate the span of the pipeline, fulfilling various jobs.

Many forms of pigs are obtainable, each built for a unique objective. Common exercises of pipeline pigging include auditing for defects, decontamination, and applying coatings.

- Pros of Pipeline Pigging

- Effects on Operational Efficiency

- Kinds of Pipeline Pigs

Effective Sanitation utilizing Pigging Solutions

Pigging solutions supply a sound answer for achieving sanitation inside passages. These processes employ dedicated apparatuses that travel through the channel layout, quickly dislodging contaminants. The routine is especially beneficial for areas that need rigorous hygiene protocols. Pigging methods supply a cost-efficient and rapid approach for disinfecting ducts, diminishing the exposure of contamination.

Picking Pigging Apparatus for Dedicated Conditions

Pigging hardware operates a significant role in effective pipeline functioning. When selecting pigging tools, it is critical to consider the specific requirements of your project. This involves assessing details such as pipeline extent, flow flux, product style, and servicing standards.

Multiple pigging options are accessible, each crafted for distinct objectives. Namely, some pigs are designed for evaluation, while others are deployed for clearing pollutants or distributing product parcels.

Furthermore, pigging equipment constituents should be harmonious with the handled content.

It is commonly recommended to consult a authority in pigging methods to ensure that you go for the most effective gadget for your customized needs.

Pipeline Cleaning Arrangements - A Profit-Driven Approach

Tubular maintenance systems provide a comprehensive selection of virtues for fields focused on pipes. By competently sanitizing and reviewing pipe interiors, pigging systems boost operational operations and lower maintenance outlays.

A primary positive of pigging systems is their aptitude to eliminate fouling such as dirt, debris, and decay products. This frequent purging promotes frictionless pipeline passage and reduces costly downtime.

Additionally, pigging systems can be used to assess the health of pipelines, revealing potential issues before they grow into substantial obstacles. This strategic technique helps to prolong durability of pipelines and minimize overall maintenance expenses.

Promoting Hygiene in Pigging Operations

Boar rearing arrangements are strongly based on appropriate hygiene actions to minimize the distribution of infections. Enforcing rigorous hygiene protocols maintains a vital milieu for pigs, therefore leads to superior health outcomes and production.

Regular cleaning and disinfection of enclosures is necessary to eliminate the amount of harmful contaminants. Proper excrement management besides operates a key part in securing hygiene.

Furthermore, {workers